Description

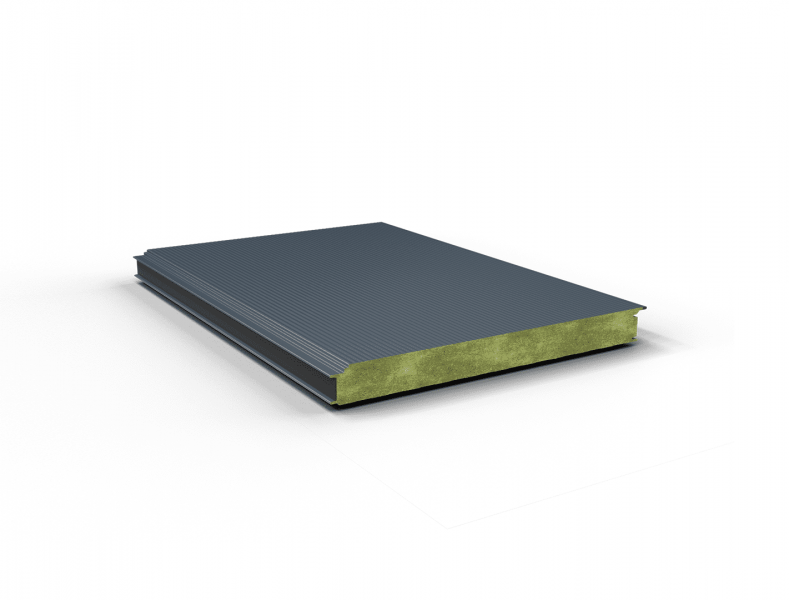

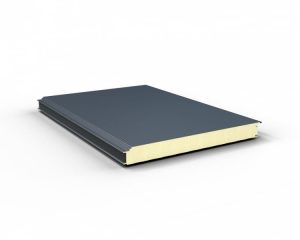

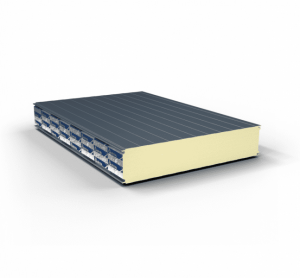

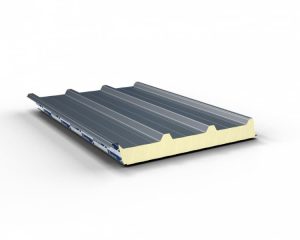

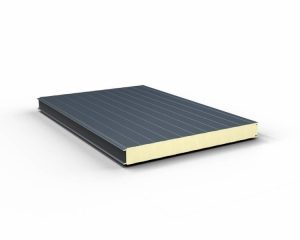

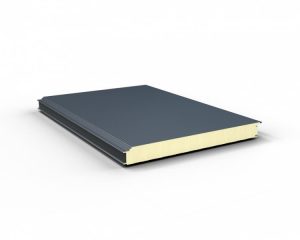

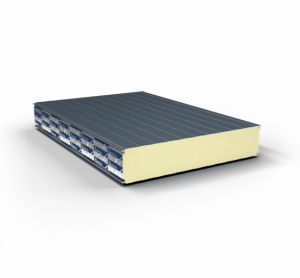

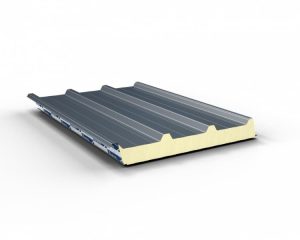

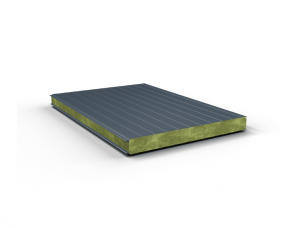

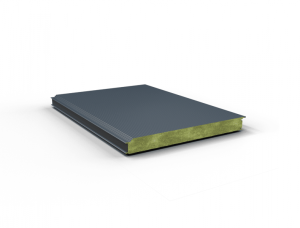

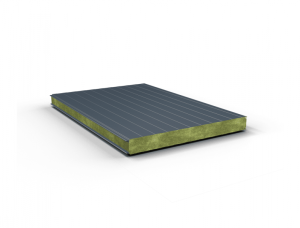

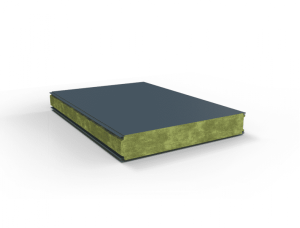

The GS MW QA U sandwich panel is a modern building element with concealed fixing, ideal for the realisation of external and internal walls in frame construction systems. Thanks to advanced production technology, these panels have a better thermal conductivity coefficient while maintaining a lower core density, which contributes to improving the energy efficiency of the building. The ability to be installed both vertically and horizontally and to be used as single- and multi-span wall elements gives designers great flexibility in shaping the architecture of buildings. The concealed fixing, which is not visible from the façade, enhances the aesthetics and elegance of the façade, making these panels particularly attractive in terms of visual and functional performance. The surface of the panels is finished with a steel sheet galvanised on both sides in accordance with EN 10346 and coated with a durable organic polyester varnish 25 μm thick, providing protection against corrosion and longevity. The panels provide superior fire protection and excellent sound insulation, making them an excellent choice for buildings with high requirements for safety and acoustic comfort.

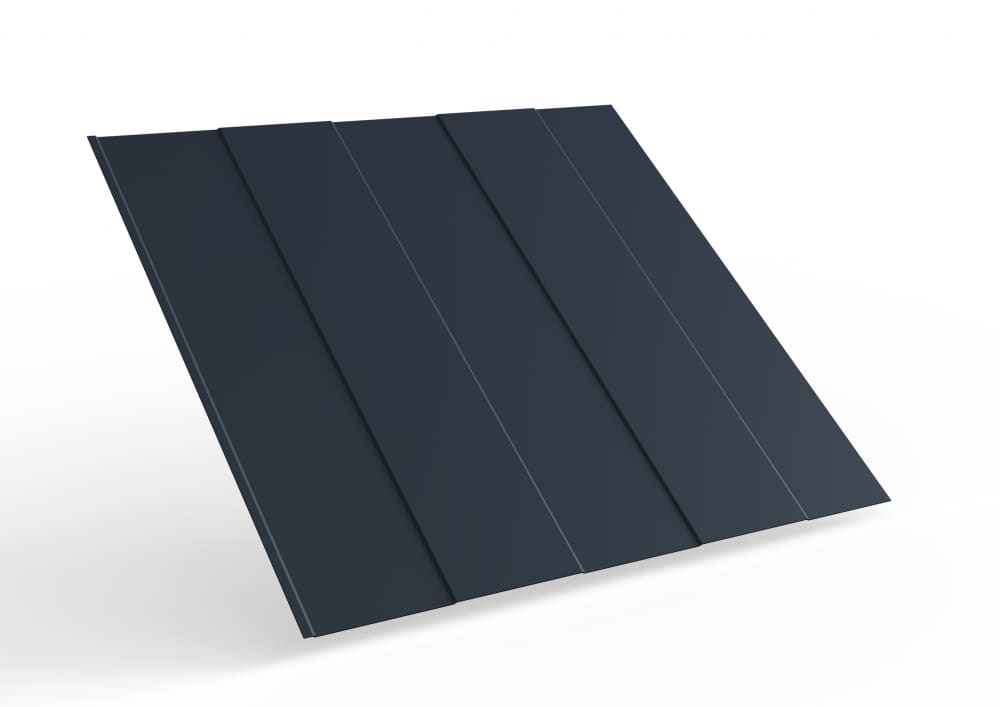

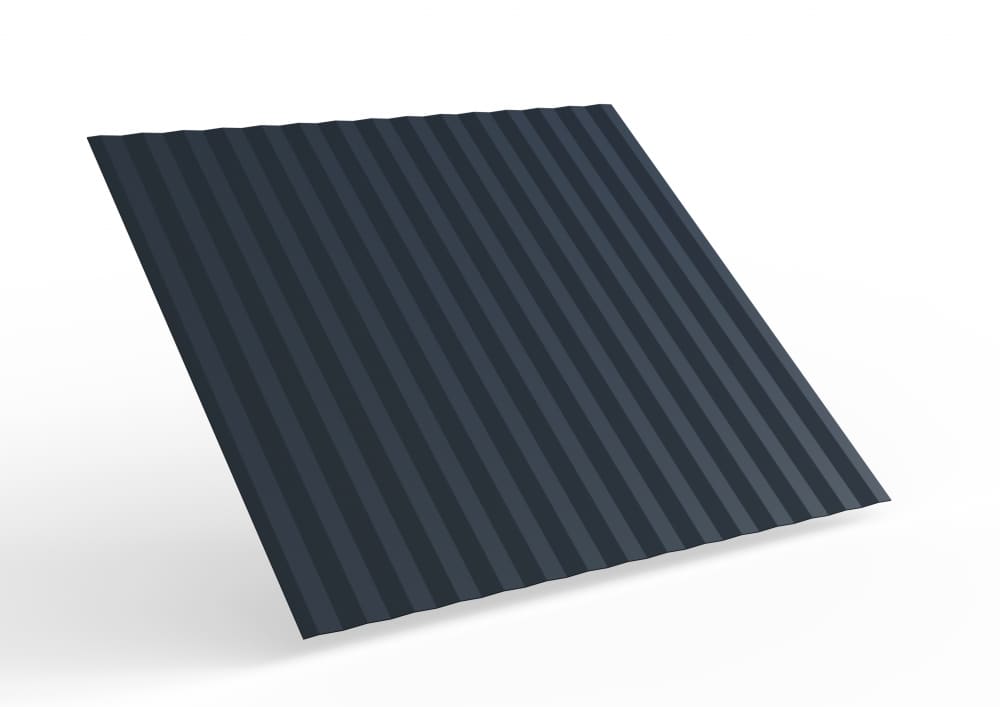

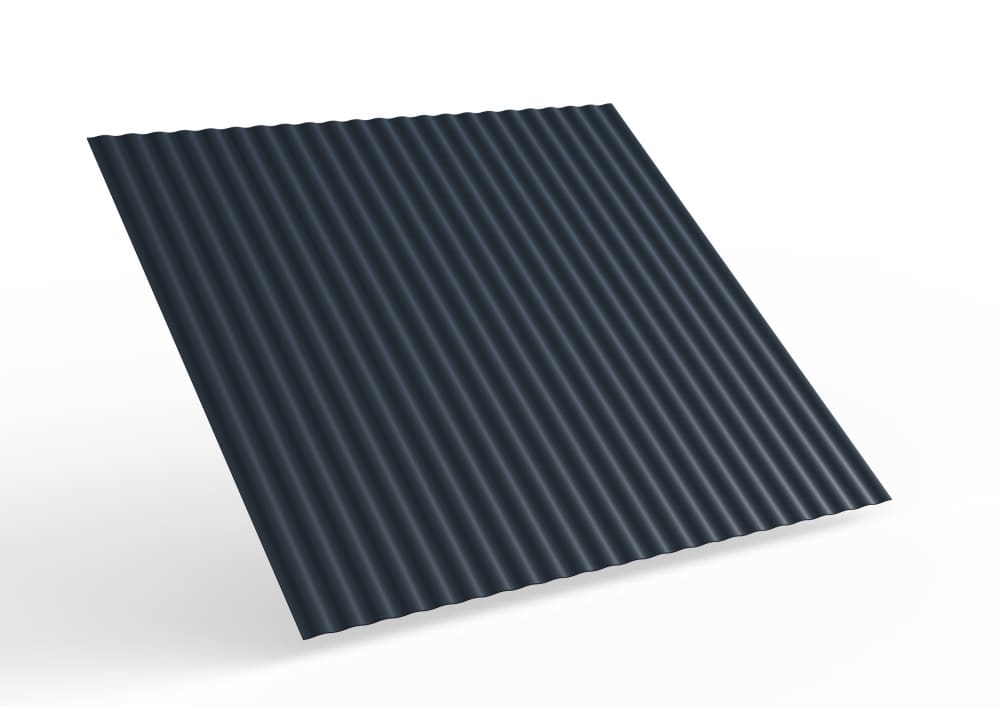

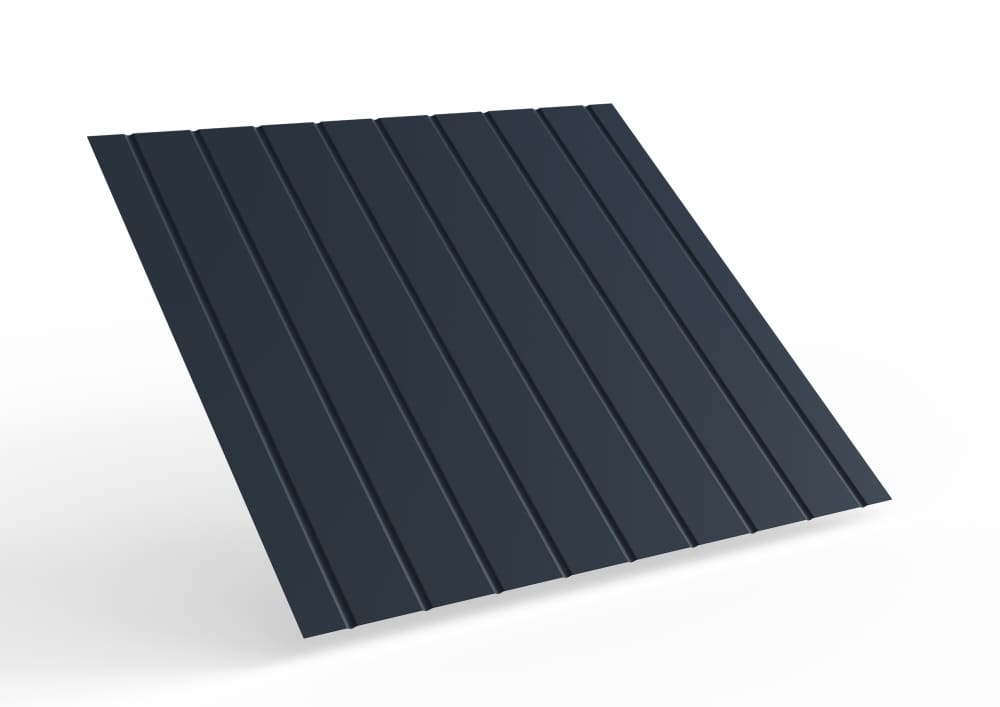

1. profiling of the tin cladding makes the walls look aesthetically pleasing

2. concealed fastener to give facades a more uniform appearance

Large lock profile radius to ensure paintwork integrity

4. auxiliary groove to facilitate positioning of the fastener

5. hard mineral wool core with very good fire resistance and acoustic insulation

Reviews

There are no reviews yet.