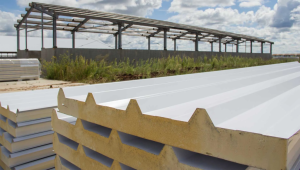

Sandwich panels have gained popularity in industrial construction due to their versatility, cost-effectiveness and technical features. In this article, we take a look at how sandwich panels can revolutionise industrial buildings, discussing their benefits and presenting application examples.

1. Benefits of Layer Boards in Industrial Buildings

1.1 Rapid Assembly

Description: One of the biggest advantages of sandwich panels is the speed of installation. Thanks to the modular system and easy-to-install components, construction time can be significantly reduced.

Benefits:

- Reduced Construction Time: Faster project completion means lower labour costs and a quicker return on investment.

- Minimising Disruption: Faster installation minimises disruption to operations, which is particularly important in industrial facilities.

Example: In the case of the construction of the new warehouse, the use of sandwich panels allowed the structure to be completed 30% faster than with traditional construction methods.

1.2 Excellent insulating properties

Description: Sandwich panels offer excellent insulation properties, both thermal and acoustic, which is crucial in industrial buildings.

Benefits:

- Thermal insulation: It reduces heating and cooling costs, which is important in large industrial facilities.

- Acoustic Insulation: Improves working comfort by reducing external and internal industrial noise.

Example: The new production facility uses sandwich panels with a polyurethane core, resulting in a thermal conductivity coefficient (λ) of 0.022 W/mK, providing excellent thermal insulation.

1.3. Resistance to atmospheric conditions

Description: Sandwich panels are designed to withstand harsh weather conditions, making them an ideal choice for industrial buildings that may be exposed to rain, wind and extreme temperatures.

Benefits:

- Moisture resistance: It protects against the growth of mould and corrosion, which is important in a humid environment.

- Fire resistance: Depending on the type of core, the panels can offer different levels of fire resistance.

Example: Mineral-core sandwich panels, which have shown excellent resistance to moisture and high temperatures, have been used in storage facilities located in high-humidity regions.

1.4 Aesthetics and Finishing Possibilities

Description: Sandwich panels offer a variety of finishing options, allowing the appearance of the building to be tailored to aesthetic and functional requirements.

Benefits:

- Size and Colour: A choice of different colours and textures can be chosen to match the existing architecture.

- Minimum Maintenance: Sandwich panel surfaces are easy to clean and maintain, which is important in industrial facilities.

Example: Sandwich panels with a metallic surface were installed in the logistics centre, which not only improved the aesthetics of the building, but also ensured ease of maintenance.

2. Examples of Layered Plate Applications in Industrial Buildings

2.1 Production halls

Description: Sandwich panels are often used for the construction of production halls, where insulation properties and resistance to harsh working conditions are key.

Example: In the state-of-the-art car factory, polyurethane-core sandwich panels were used for the walls and roofs, providing excellent thermal and acoustic insulation while reducing construction time.

2.2 Warehouses

Description: Sandwich panels are the ideal solution for warehouses where both insulation properties and weather resistance are important.

Example: Sandwich panels with increased moisture and fire resistance were used in the large logistics warehouse, ensuring the safety of stored goods and the long-term use of the facility.

2.3 Logistics centres

Description: Logistics centres that require large spaces and effective insulation can benefit from the advantages of sandwich panels in terms of speed of installation and insulation properties.

Example: In the distribution centre, sandwich panels were used for the walls and ceilings, allowing the construction to be completed quickly and minimising operating costs.

2.4 Commercial and Office Facilities

Description: Sandwich panels can be used in commercial and office buildings where aesthetics, energy efficiency and speed of installation are key.

Example: The new office complex uses sandwich panels with an aesthetically pleasing finish, improving the appearance of the building while providing excellent thermal and acoustic insulation.

3 Guidance to Designers

3.1 Choosing the Right Type of Plate

Description: Choosing the right type of sandwich panel depends on the specific requirements of the project, such as thermal insulation, acoustic insulation, fire resistance and aesthetics.

Directions:

- Insulation: Choose boards with the right insulation core depending on your thermal and acoustic needs.

- Resilience: Check what resistance properties are required in your environment.

- Aesthetics: Decide on the finish and colour that best suits your design and aesthetic requirements.

3.2 Cooperation with suppliers

Description: Working with experienced suppliers and manufacturers of sandwich panels can provide access to the latest technologies and solutions tailored to a project's specific needs.

Directions:

- Consultation: Take expert advice on material selection and design.

- Samples: Order material samples to assess their properties and fit with the project.

3.3 Assembly planning

Description: Developing an installation plan and coordinating construction work can help to make effective use of sandwich panels.

Directions:

- Schedule: Create a detailed installation schedule to make the most of the benefits of rapid sandwich panel installation.

- Quality control: Regularly monitor the quality of workmanship and ensure adherence to technical specifications.

Summary

Sandwich panels offer a number of benefits for industrial buildings, including rapid installation, excellent insulation, resistance to harsh weather conditions and aesthetic finish options. Their use in various types of industrial buildings can help reduce construction costs, increase energy efficiency and improve occupant comfort. Choosing the right sandwich panels and carefully planning