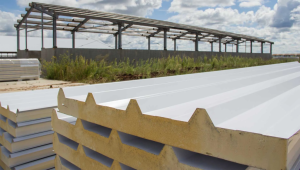

Sandwich panels, known for their functionality and versatility, are gaining increasing attention in the context of sustainable construction. Their insulating properties, durability and cost-effectiveness make them an attractive choice for many building projects. However, nowadays, there is an increasing focus on their environmental impact when choosing building materials. Here is a detailed discussion of the environmental aspects of using sandwich panels:

1. Materials and Production Process

a. Types of Cores and Coatings:

- Sandwich panels are manufactured with different core materials, such as polyurethane, polystyrene, mineral wool or recycled cores. The choice of core material has a direct impact on the energy efficiency of the building and its environmental impact.

- Ecological options: Choosing cores made from recycled materials or those with a lower environmental impact can reduce a building's carbon footprint.

b. Emissions and Energy Consumption:

- The manufacturing process of sandwich panels can involve CO2 emissions and other harmful substances, especially in the case of polyurethane cores. It is worth checking whether the manufacturer uses emission-reducing technologies and what environmental standards are applied in production.

Insulating properties and energy efficiency

a. Thermal Insulation:

- Sandwich panels have excellent insulation properties, which translates into lower energy consumption for heating and cooling buildings. This directly contributes to the reduction of CO2 emissions associated with the operation of the building.

b. Energy Efficiency of Buildings:

- High-quality sandwich panels can contribute to energy efficiency certifications such as LEED or BREEAM. They support the construction of more sustainable buildings that are more energy efficient and have a lower environmental impact.

3 Recycling and Recovery

a. Recycling of Layer Boards:

- Sandwich panels can be recycled at the end of their life, although the process can be complex depending on the materials used in production. It is worth noting the recycling options offered by manufacturers and local regulations for the disposal of building materials.

b. Opportunities for Core Recycling:

- With recycled cores, such as panels with a core made from recycled materials, the environmental impact can be significantly reduced. It is worth investing in building materials that offer such eco-friendly solutions.

4. Sustainability and Lifespan

a. Resistance to Atmospheric Agents:

- Sandwich panels are resistant to moisture, fire and mechanical loads, which translates into the longevity of the material. Longer service life means less need for replacement and refurbishment, which reduces construction waste.

b. Reducing the Need for Maintenance:

- Due to their durability and resistance to damage, sandwich panels reduce the need for frequent maintenance and repairs, which also results in less consumption of resources and materials over a longer lifetime.

5. Sustainability Practices in Production

a. Organic Producer Initiatives:

- Some sandwich panel manufacturers are implementing sustainable practices, such as using renewable energy sources in the production process, minimising waste and optimising production processes.

b. Organic Certification:

- It is worth checking whether the sandwich panel manufacturer has environmental certifications, such as ISO 14001 or certificates confirming the use of environmentally friendly materials.

Summary

Sandwich panels can be an environmentally friendly choice in construction, provided the right choice of materials and manufacturers is made and a conscious approach to recycling and energy efficiency is taken. Selecting materials with a low environmental impact, promoting sustainability in the production process and ensuring the longevity and energy efficiency of buildings are key aspects that contribute to the environmental performance of sandwich panels. Through these practices, you can significantly reduce your carbon footprint and contribute to building more sustainable facilities.