Modular construction is gaining popularity due to its flexibility, speed of implementation and cost-effectiveness. Sandwich panels play a key role in this dynamic field of construction, offering a range of benefits that speed up the construction process and improve the quality of final structures. Here's how sandwich panels can revolutionise modular construction:

1. Accelerating the Construction Process

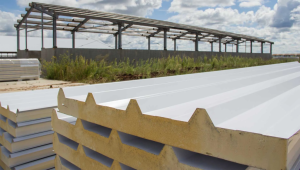

Sandwich panels are known for their ease of assembly and quick installation, which is key in modular construction. Due to their prefabricated nature, building components can be manufactured in the factory and then transported to the site as finished modules. This significantly reduces construction time on site, minimising the need for further finishing work.

- Example: The construction of temporary offices for a major construction project, where sandwich panels are used to quickly erect lightweight, functional structures that can be easily repositioned or modified as required.

2. Cost reduction

Thanks to prefabrication and ease of installation, sandwich panels can help reduce construction costs. Fewer on-site needs mean lower labour costs and shorter lead times. In addition, their energy-saving properties can lead to lower building operating costs in the future.

- Example: The use of sandwich panels in residential construction, where cost efficiency allows projects to be more affordable, benefiting both investors and future residents.

3. Design flexibility

Sandwich panels allow great flexibility in the design of modular buildings. They can be used in a variety of configurations, from simple structures to more complex designs with different shapes and finishes. This gives architects and designers a wide range of options to create innovative and aesthetically pleasing solutions.

- Example: An innovative office with modular living units where sandwich panels allow complex spatial layouts such as offices with open workspaces and enclosed private areas.

4. Energy efficiency

Sandwich panels have excellent insulation properties, which is crucial for modular buildings that often have to meet specific energy efficiency standards. Thanks to their insulating cores, sandwich panels help maintain indoor comfort and reduce heating and cooling costs.

- Example: Modular holiday homes fitted with sandwich panels that provide excellent thermal insulation to effectively manage internal temperatures in different climatic conditions.

5. Durability and safety

Sandwich panels are resistant to various external influences, such as moisture, fire or mechanical loads, which increases the durability and safety of modular buildings. These properties are particularly important in the context of buildings designed for intensive use or located in harsh environments.

- Example: The use of sandwich panels in storage or industrial buildings, where their resistance to atmospheric and mechanical factors ensures the longevity of the structure and the safety of stored goods.

6. Sustainable Development

In the context of sustainability, sandwich panels can be made from recycled materials or those that are more environmentally friendly. Combined with their energy efficiency, they contribute to building greener structures.

- Example: A modular public building with sandwich panels made from recycled materials that meets environmental standards and sustainable building certifications.

Summary: Sandwich Panels in Modular Construction: The Fast and Efficient Way to Build

Sandwich panels are a key element of modern modular construction, offering a fast, efficient and cost-effective way to complete building projects. Their advantages, such as speed of installation, design flexibility, energy efficiency and durability, make them ideal for a wide variety of building applications. Exploring and exploiting the potential of sandwich panels can make a significant contribution to the success of projects in modular construction.