Acoustics in industrial buildings is one of the key aspects that has a direct impact on working comfort, safety and production efficiency. Noise, a common problem in such facilities, can have a negative impact on workers' health, leading to stress, fatigue and even hearing damage. Therefore, more and more investors and designers are turning their attention to solutions that help reduce noise and improve acoustics in industrial spaces. One such solution is sandwich panels. In this article, we look at how sandwich panels can affect acoustics in industrial buildings, improving comfort and safety.

The importance of acoustics in industrial buildings:

- Impact of noise on workers' health and productivity: High noise levels in workplaces can lead to a number of negative health effects, such as fatigue, stress, sleep disturbance and even permanent hearing damage. From an employer's perspective, noise can also affect employees' concentration and productivity, resulting in lower production efficiency and a higher risk of accidents.

- Noise standards and regulations: Many countries have strict standards for maximum noise levels in the working environment, set by health and safety regulations. Proper acoustic management in industrial buildings is key to meeting these requirements and ensuring safe working conditions.

How can sandwich panels improve acoustics in industrial buildings?

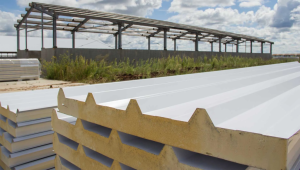

- Sound-absorbing properties of sandwich panels: Sandwich panels, especially those with a mineral wool core, have excellent sound-absorbing properties. Due to its porous structure, mineral wool effectively absorbs sound, reducing noise levels inside the building. This makes these panels an ideal material for use in buildings with high noise levels, such as production halls, workshops and warehouses.

- External noise reduction: In industrial buildings, it is not only the noise generated inside that is a problem. Often these buildings are located in industrial areas where external noise (e.g. traffic, construction work) can put additional strain on workers. Sandwich panels, thanks to their insulating properties, can effectively reduce the transmission of external noise into the building, thus improving working conditions.

- The use of perforated sandwich panels: For even better acoustic control, perforated sandwich panels are used in some industrial projects. The perforations on the surface of the panels further improve their sound absorption properties, allowing for even more effective noise reduction. These types of panels are particularly recommended in areas where high frequency sounds are generated.

- Sound insulation between rooms: In many industrial buildings, such as factories or production facilities, there is a need for sound insulation between different functional zones (e.g. offices next to the production hall). Sandwich panels can be used as sound-absorbing partitions that effectively separate noisy zones from those that require silence and concentration.

Examples of applications of sandwich panels in industrial buildings:

- Production halls: In large production halls, where many noise-generating machines are in operation, sandwich panels with a mineral wool core are often used for walls and ceilings. Their sound-absorbing properties help to keep noise levels at an acceptable level, improving working comfort and safety.

- Warehouses and logistics centres: In warehouses and logistics centres, where vehicle traffic and loading operations generate noise, sandwich panels can be used to build sound-absorbing partitions that separate work areas from office or social areas.

- Technical rooms: In industrial buildings, such as processing plants or power stations, sandwich panels are often used for technical rooms that house noisy machinery or equipment. By using sandwich panels, the noise generated by this equipment is effectively isolated, minimising its impact on the rest of the building.

Acoustic benefits of sandwich panels:

- Improving working conditions: The reduction in internal and external noise directly translates into better working conditions, which in turn contributes to higher employee productivity and health.

- Meeting standards and regulations: Thanks to the excellent acoustic properties of sandwich panels, companies can more easily comply with current noise regulations in the working environment, thus avoiding sanctions and penalties.

- Energy efficiency: Sandwich panels not only improve the acoustics, but also the thermal insulation of buildings, resulting in lower heating and cooling costs.

Sandwich panels

Summary: Boards layered are one of the most effective solutions for improving acoustics in industrial buildings. Thanks to their application, it is possible to effectively reduce noise, both internal, as well as externally, resulting in improved working conditions, safety and compliance with current standards. Investors and designers who choose sandwich panels gain not only a high-quality building material, but also a tool to optimise acoustics in industrial buildings. As a result, such solutions contribute to the creation of working spaces that are friendlier, safer and more efficient, which has a direct impact on the success of any business.