Building a sandwich panel house is a quick, easy and cost-effective way to achieve a warm, quiet and durable building. Here is a detailed step-by-step guide to the process of building a sandwich panel house:

Stage 1: Design and foundations

- Project: The first step is to draw up a construction design that takes into account the specifics of the sandwich panels and their use in the building structure. The design should include details of the thickness of the walls, the type of insulation, the location of window and door openings, and other relevant structural elements.

- Foundations: Once the design has been approved, the foundations should be constructed. Sandwich panels are lightweight, which allows for shallow foundations. However, care must be taken to properly insulate the foundations to prevent moisture penetration into the building.

Stage 2: Installation of external walls

- Rack assembly: A frame of steel or timber profiles is mounted on the foundations. The frame is the load-bearing structure for the external walls.

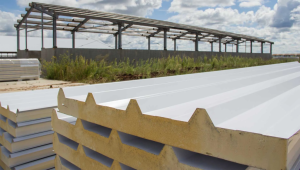

- Installation of sandwich panels: The sandwich panels are fixed to the frame with screws or bolts. Appropriate seals must be used to ensure airtightness and thermal insulation of the walls.

- Installation of windows and doors: Windows and doors are installed in the designated openings in the sandwich panels. Appropriate installation profiles and seals must be used to ensure the tightness and thermal insulation of the window and door joinery.

Stage 3: Installation of the roof

- Roof construction: The roof structure can be made of wood or steel. Appropriate insulation materials should be used to ensure the thermal and acoustic insulation of the roof.

- Roofing: Roofing can be made from a variety of materials, such as tiles, sheet metal or shingles. Appropriate insulation and sealing materials should be used to ensure the roof is airtight and durable.

Stage 4: Interior finishing

- Insulation: Once the walls and roof have been installed, internal insulation must be carried out. Insulation can be made of various materials such as mineral wool, polystyrene or polyurethane foam.

- Installations: The building's electrical, plumbing and heating systems are to be installed.

- Wall and floor finishes: The walls and floors can be finished in any way you like, according to your own preferences.

Stage 5: Technical acceptance and operation

Once the finishing work has been completed, the building must be submitted for technical acceptance. Once the acceptance is positive, the building can be put into use.

House construction with sandwich panels

Advantages of building a house with sandwich panels:

- Rapid construction: Building a house with sandwich panels is much faster than building with traditional building materials such as brick or hollow block.

- Easy to install: Sandwich panels are easy to install, which reduces labour costs.

- Excellent thermal and acoustic insulation: Sandwich panels provide excellent thermal and acoustic insulation, which reduces the heating and cooling costs of a building, as well as providing acoustic comfort.

- High strength and resistance: Sandwich panels are highly durable and resistant to weather conditions such as rain, snow, wind and UV radiation.

- Lightweight design: Sandwich panels are lightweight, which reduces the load on the building structure.

- Aesthetic appearance: Sandwich panels are available in different colours and textures, which allows for an aesthetically pleasing appearance of the building.