Sandwich panels is a modern building material that has gained immense popularity in various fields of construction due to its versatility and properties. In this article, we will take a closer look at what sandwich panels are, how they are constructed and their properties. This will give you a better understanding of why they are so highly valued in industrial and residential construction

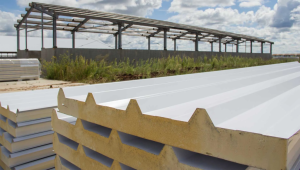

Sandwich panels consist of three main components: a core and two facings. This design allows them to combine different properties and provide effective building solutions.

- Core: The core of the sandwich panel is located between the two facings and acts as insulation. Depending on the type of core, the panels can have different thermal, acoustic and fire properties. Here are the most common types of core:

- Polyurethane (PUR): It exhibits excellent insulating properties, is lightweight and resistant to moisture. Polyurethane is often used in buildings where good thermal insulation is crucial.

- Mineral wool: Known for its high fire resistance and good acoustic properties. Mineral wool is ideal for buildings where additional fire protection is required.

- Polystyrene (EPS): An economical option with good thermal properties. Styrofoam is widely used in construction where cost is an important factor.

- Composite paper core: Mainly used in applications requiring high strength and light weight, for example in panels for the transport industry.

- Cladding: Panel facings are the outer layers that protect the core and give the panel its final appearance. They can be made from a variety of materials, including:

- Sheet steel: The most commonly used cladding, which is durable and resistant to various atmospheric agents. Sheets can be galvanised, painted or coated with protective coatings.

- Aluminium: Lighter than steel and more resistant to corrosion. Aluminium is used in specialised applications where additional corrosion resistance is required.

- PVC (polyvinyl chloride): Used mainly in industrial buildings where aesthetics are less important and durability and ease of maintenance are key.

2. operation principle of sandwich panels

Sandwich panels are designed to effectively perform an insulating function. Their performance is based on the principle that the core between the facings forms a barrier to heat and sound conduction. Here is how each property works:

- Thermal insulation: The core of a sandwich panel acts as an insulator, minimising heat loss and improving the energy efficiency of buildings. Polyurethane and polystyrene, due to their low thermal conductivity, effectively maintain the temperature inside the building, which can lead to savings on heating and cooling.

- Sound insulation: Sandwich panels with a core of mineral wool or other high-density materials effectively dampen noise. This makes them ideal for buildings where acoustic control is important, such as offices, hotels and residential buildings.

- Fire resistance: Mineral wool and other fire-resistant materials in the core of sandwich panels provide additional fire protection. These panels can meet a variety of fire standards, which is important in public and industrial buildings.

3 Benefits of using sandwich panels

Sandwich panels offer many benefits that make them a popular choice for construction:

- Rapid assembly: Thanks to its prefabrication and easy-to-install construction, sandwich panels allow the construction to be completed quickly and efficiently. The installation time is significantly shorter compared to traditional construction methods.

- Effective cost: Although the initial cost of sandwich panels may be higher, their insulating properties and rapid installation can lead to savings on the running costs of a building. The long-term energy-saving benefits can outweigh the initial investment costs.

- Multifunctionality: Sandwich panels are versatile and can be used in different parts of a building - from walls to roofs and facades. Their diversity in cladding and cores allows them to be tailored to specific project needs.

- Aesthetics: Sandwich panels can come in a variety of surface finishes to suit the aesthetics of the building. They can be painted, covered with different coatings or used in original architectural designs.

4 Examples of use

Sandwich panels are used in a variety of building types and projects:

- Industrial halls and warehouses: Due to their insulating properties and quick installation, sandwich panels are an ideal choice for large industrial buildings and warehouses.

- Residential buildings: Increasingly used in residential construction, where their insulating and aesthetic properties contribute to the comfort of the occupants.

- Building facades: Sandwich panels are used to create modern and functional facades that combine aesthetics with functionality.

Summary

Sandwich panels are a modern building solution that combines various insulating and aesthetic properties. Thanks to their construction, operating principles and benefits, they are a versatile material, which performs well in a variety of building applications. Understanding how sandwich panels work and what properties they have will help you make an informed decision when choosing materials for building construction or renovation.