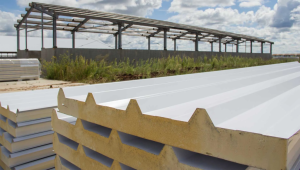

Choosing the right insulation materials is crucial for the energy efficiency and comfort of buildings. Sandwich panels, known for their wide use in construction, offer unique properties that set them apart from other insulation solutions. In this post, we will benchmark sandwich panels against other common insulation materials such as mineral wool, polystyrene and plasterboard.

1. Insulating Effectiveness

Layer boards:

- Thermal insulation: Sandwich panels provide excellent thermal insulation thanks to a core of material with a high thermal conductivity coefficient (λ), such as polyurethane, mineral wool or polystyrene. As a result, these panels effectively prevent heat loss in winter and overheating in summer.

- Acoustic Insulation: Sandwich panels can also offer excellent acoustic properties, which is important in industrial, office and residential buildings.

Comparison:

- Mineral Wool: Excellent thermal and acoustic insulation, but may require additional cladding materials to be fully effective.

- Styrofoam: It insulates well thermally, but is less effective in terms of sound insulation. It also requires additional protection against mechanical damage.

- Plasterboard: Mainly used for acoustic and fire insulation, but their thermal insulation properties are limited compared to sandwich panels.

2. cost

Layer boards:

- Cost of Purchase: Sandwich panels can be more expensive to buy than some traditional insulation materials, but their advantages in terms of insulation and speed of installation can compensate for the higher cost.

- Cost of Assembly: Due to the ease of installation and the minimal number of layers required, labour costs can be lower compared to materials that require more complex application.

Comparison:

- Mineral Wool: It may be cheaper to buy, but the cost of installation is usually higher due to the need for precise placement and additional materials.

- Styrofoam: Relatively cheap, but requires careful installation to avoid thermal bridges and mechanical damage.

- Plasterboard: Low purchase costs, but additional costs for installation and finishing can add to overall costs.

3. Durability and Resilience

Layer boards:

- Moisture resistance: Sandwich panels, especially those with a core of moisture-resistant materials, perform well in humid conditions, making them suitable for harsher weather applications.

- Fire resistance: Depending on the type of core, sandwich panels can offer different levels of fire resistance. Many are certified for fire resistance.

- Persistence: Sandwich panels are resistant to mechanical damage, making them durable and long-lasting.

Comparison:

- Mineral Wool: Good resistance to moisture and fire, but can be susceptible to mechanical damage and requires adequate protection.

- Styrofoam: Sensitive to moisture and mechanical damage. May require additional protection to retain its insulating properties.

- Plasterboard: They cope well with fire, but are less resistant to moisture and can suffer mechanical damage, especially in high humidity conditions.

4 Assembly time

Layer boards:

- Speed of Assembly: Sandwich panels are designed for quick and easy installation, which can significantly reduce project times. They require less application time compared to traditional insulation methods.

Comparison:

- Mineral Wool: Installation can be time-consuming and requires a precise fit and the use of additional insulation materials.

- Styrofoam: Quick to install, but may require careful fitting and additional protection from damage.

- Plasterboard: They require more time to install as they are often installed in layered systems with additional finishing materials.

5 Application possibilities

Layer boards:

- Versatility: Sandwich panels are versatile in both industrial and residential buildings. They can be used for walls, roofs and facades, offering a variety of finish and aesthetic options.

Comparison:

- Mineral Wool: Often used as wall and roof insulation in residential and commercial buildings, but its use in facades can be limited.

- Styrofoam: Mainly used for external wall and foundation insulation. Its use in roof structures may be limited.

- Plasterboard: Mainly used internally for partition walls and ceilings, rarely in external applications.

Summary

Sandwich panels offer a number of benefits that can outweigh other insulation materials, including improved insulation efficiency, speed of installation and versatility of use. Although they can be more expensive to purchase, Their long-term benefits, including savings on energy and maintenance costs, can make them a viable choice for many building projects.