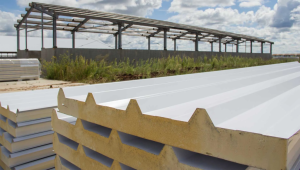

Choosing the right sandwich panels for a building project can be a key factor in the efficiency, durability and aesthetics of a building. Sandwich panels are versatile and available in different variants, which can make it easier to adapt them to the specific requirements of a project. In this article, we will discuss in detail how to make the right choice of sandwich panels, taking into account various technical, aesthetic and economic aspects.

1. Definition of project requirements

Before choosing sandwich panels, it is important to determine the exact requirements of your building project. Here are the key factors to consider:

- Building type:

- Industrial: Production halls, warehouses, distribution centres.

- Residential: Single-family houses, multi-family buildings, flats.

- Utilities: Offices, hotels, sports facilities.

- Insulation requirements:

- Thermal insulation: Important in buildings where temperature control is important.

- Sound insulation: Crucial in facilities where noise is a problem, such as offices and flats.

- Fire resistance: Important in areas where high fire protection is required.

- Weather conditions:

- Humidity: Requires a moisture-resistant board.

- Extreme temperatures: The boards must be able to withstand temperature changes.

2. selection of the sandwich panel core

The core of a sandwich panel plays a key role in its insulating and mechanical properties. Here's how to choose the right core:

- Polyurethane (PUR):

- Pros: Excellent thermal insulation, lightweight, moisture-resistant.

- Application: Ideal for buildings where energy efficiency and resistance to changes in humidity are key.

- Mineral wool:

- Pros: High fire resistance, good sound insulation.

- Application: Suitable for buildings requiring fire protection and noise reduction, such as residential buildings or offices.

- Polystyrene (EPS):

- Pros: Economical option, good thermal insulation, low weight.

- Application: Used in buildings where cost is a key factor but exceptional fire performance is not required.

- Composite paper core:

- Pros: Lightweight, high strength.

- Application: Often used in transport and specialist applications where high strength and lightness are required.

3. cladding selection

The cladding of sandwich panels affects the aesthetics, durability and functionality of the panel. Here are the key options:

- Sheet steel:

- Pros: Durability, weatherproof, paintable.

- Application: Often used in industrial buildings, warehouses and commercial premises.

- Aluminium:

- Pros: Lightweight, corrosion-resistant, aesthetically pleasing.

- Application: Ideal for applications where corrosion resistance is key, such as coastal facilities.

- PVC (polyvinyl chloride):

- Pros: Low weight, easy to maintain, chemical resistant.

- Application: Used in industrial buildings and facilities where aesthetics are not a priority.

4 Cost analysis

The cost of sandwich panels can vary depending on the type of core, the cladding, and the amount of material. It is worth analysing:

- Cost of purchase: Compare prices of different types of sandwich panels.

- Cost of installation: Take into account the costs associated with installation, which can vary depending on the type of board and the difficulty of installation.

- Operating cost: Boards with better insulation can lead to savings in heating and cooling costs.

5. requirements of local building regulations

Check local building regulations for insulation, fire resistance and other properties of sandwich panels before you make your choice. Some regions may have specific requirements that must be met.

6. aesthetics and design fit

The aesthetics of sandwich panels are also important, especially in construction projects where the appearance of the building matters. Choose panels that harmonise with the overall style of the project. Finishing options, such as painting or decorative coatings, can help achieve the desired look.

7. Selection of supplier and contractor

Choosing the right sandwich panel supplier and installation contractor is just as important as choosing the material itself. Make sure you choose proven and experienced suppliers and professionals who will provide high quality materials and service.

Summary

Choosing the right sandwich panels for a building project requires consideration of many factors, such as building type, insulation requirements, weather conditions, cost, aesthetics and building regulations. Analysing all of these aspects will help you make the best choice for optimum building functionality, durability and aesthetics. Understanding, how different types of sandwich panels can meet the specific needs of a project, will enable you to make an informed decision and ensure the success of your construction project.