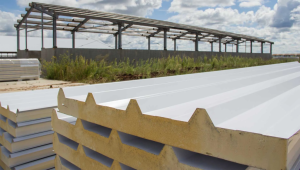

Modern technologies used in the manufacture of sandwich panels:

The production of sandwich panels is constantly evolving, and new technologies are making it possible to create panels with increasingly better properties and parameters. Here are some examples of modern technologies used in composite panel production:

- Laser cutting: a precision cutting method for steel that ensures smooth edges and minimises waste, guaranteeing the high quality and accuracy of the panels.

- Automated production lines: using robots and computer control systems to perform multiple tasks, increasing production efficiency and accuracy and reducing the risk of human error.

- New insulation materials: such as PIR and XPS foam provide better thermal and acoustic insulation than traditional materials such as mineral wool, and are also lighter and easier to install.

- Protective coatings: protect sandwich panels against corrosion, UV radiation and other external factors, extending their life and improving their aesthetics.

- Digital printing technologies: allow any patterns and graphics to be applied to the discs, creating personalised discs with a unique look.

Advantages of using modern technology in the manufacture of sandwich panels:

- Higher quality: improved properties and performance of sandwich panels.

- Greater efficiency: lower production costs.

- Better insulation: energy saving and comfort.

- Longer service life: reducing the risk of disc damage.

- Greater aesthetics: the unique and aesthetically pleasing appearance of the panels.

Modern technologies in the production of sandwich panels are a guarantee of high quality, efficiency and aesthetics. Manufactured using the latest technology, sandwich panels are the ideal material for the construction of various types of buildings.