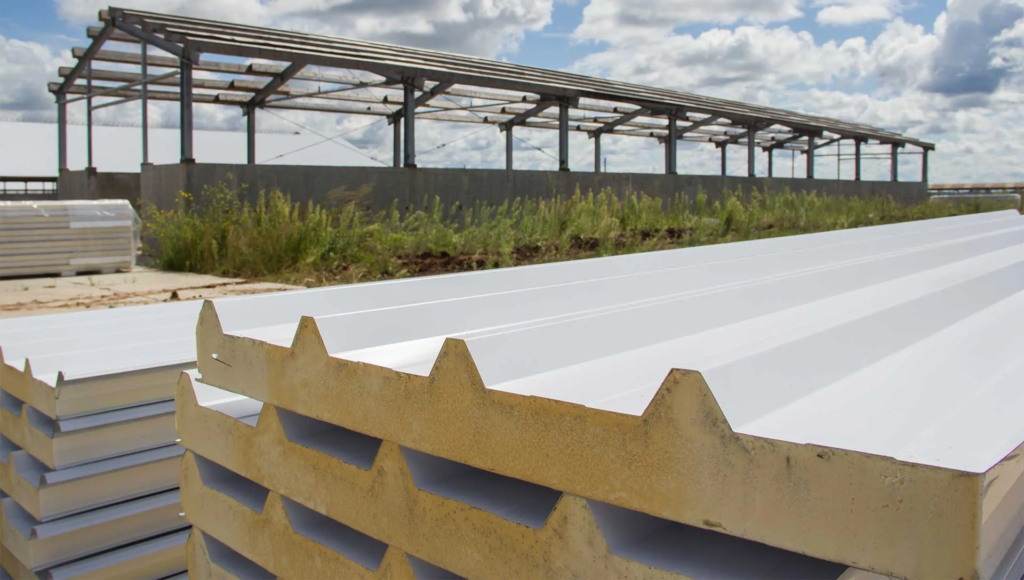

Nowadays, architects, designers and investors are increasingly looking for solutions that not only meet technical requirements, but also allow unique, aesthetic and functional building projects to be realised. Sandwich panels, thanks to their versatility and personalisation options, are becoming a key material that can be tailored to the specific needs of each project. In this article, we will discuss how sandwich panels can be personalised to fit perfectly into individual building requirements, both functionally and aesthetically.

Customisation options for sandwich panels:

- Choice of insulation core: Sandwich panels consist of an insulating core, which is responsible for their thermal and acoustic properties. Depending on the needs of the project, there are different types of core to choose from:

- Polyurethane (PUR) and polyisocyanurate (PIR): They feature excellent thermal insulation, making them an ideal choice for buildings where maintaining a stable temperature is crucial, such as cold stores and production halls.

- Mineral wool: It offers exceptional fire resistance and good sound absorption properties, making it a great choice for buildings requiring high levels of fire safety and sound insulation.

- Polystyrene (EPS): A popular choice for its light weight and good insulation, ideal for buildings with lower thermal requirements but limited budgets.

- Personalisation of colours and finishes: Sandwich panels offer a wide range of colours and finishes that can be customised to suit the aesthetic requirements of the project:

- Colour palette: Thanks to the wide choice of colours, it is possible to match the panels to a company's corporate identity or to harmonise them with their surroundings. Manufacturers often offer panels in standard RAL colours, but it is also possible to order panels in non-standard shades.

- A variety of surface finishes: Sandwich panels can have different finishes, such as smooth, corrugated, matt, glossy or metallic. This allows the desired aesthetic effect to be achieved, such as a modern, industrial look or a more classic, elegant design.

- Protective coatings: Additional coatings, such as those resistant to UV radiation, chemicals or corrosion, can be applied depending on the environment in which the panels will be used. Such solutions provide long-lasting protection and maintain aesthetics for years to come.

- Adjustment of panel thickness and dimensions: Each building project has its own unique requirements for thermal insulation, acoustic insulation and mechanical strength. Sandwich panels can be personalised in terms of core thickness and dimensions:

- Core thickness: Depending on the insulation requirements, panels with different core thicknesses are available. Thicker boards provide better thermal insulation, which is important in energy-efficient or passive buildings.

- Plate dimensions: The standard dimensions of the panels can be adapted to the specifics of the project. Many companies offer to cut the panels to size, which minimises waste and speeds up installation on site.

- Personalisation of additional functions: Depending on the specific needs of the project, the sandwich panels can be equipped with additional features:

- Acoustic perforations: In buildings where acoustic control is crucial, such as concert halls and sports halls, sandwich panels can be perforated to improve their sound-absorbing properties.

- Integration with assembly systems: Adaptability of the panels to different mounting systems, such as concealed fixings, which enhances the aesthetics of the façade by eliminating visible fixings.

- Antimicrobial coatings: In facilities such as hospitals, laboratories or food processing plants, antibacterial coatings can be used to support the maintenance of a high level of hygiene.

Examples of applications for personalised sandwich panels:

- Modern office buildings and business centres: Architects are increasingly turning to sandwich panels to create modern, aesthetically pleasing office building facades. With customisable colours and finishes, office buildings can be given a unique character that sets them apart from other buildings.

- Industrial and warehouse buildings: In industrial buildings, the personalisation of sandwich panels in terms of functionality, such as corrosion resistance or ease of cleaning, is key. This makes the buildings not only practical, but also durable and easy to maintain.

- Sports and leisure facilities: In sports halls and other leisure facilities, personalised sandwich panels with acoustic perforations can improve acoustic comfort while offering an aesthetic finish that promotes modern design.

Sandwich panels

Summary: The personalisation of sandwich panels opens up enormous possibilities for architects and builders to create building designs that are both functional and aesthetically pleasing. With a choice of core, colour, finish, dimensions and additional features, sandwich panels can be perfectly tailored to the specific requirements of each project. Regardless of, whether the project is for a modern office building, an industrial hall or a sports facility, personalised sandwich panels can help achieve the desired end result, meeting all technical and aesthetic expectations.