Description

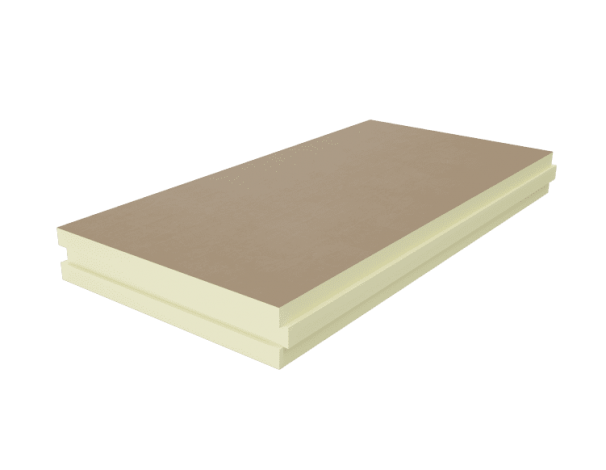

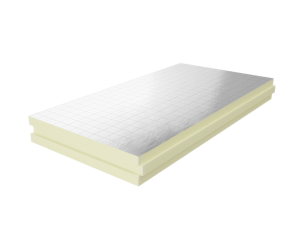

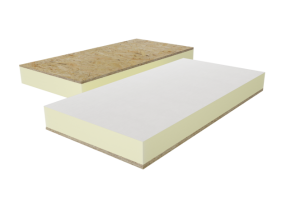

PIR termPIR® AGRO P REV insulation board is a modern and effective solution that significantly increases the energy efficiency of buildings. The boards consist of a thermally insulating core made of rigid PIR foam, which provides excellent insulation properties. They are protected on both sides by a gas-tight sandwich cladding consisting of a laminate of aluminium and polyethylene (Agro P), with the aluminium layer facing inwards towards the PIR core. This solution makes termPIR® AGRO P REV panels ideally suited for contact with materials that may react with aluminium, offering durability and reliability in demanding conditions. Find out more about this innovative solution and how it can improve the energy efficiency of your project.

Reviews

There are no reviews yet.