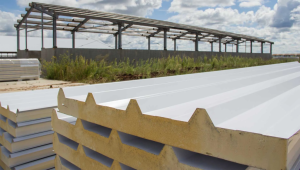

In the face of increasing environmental challenges, the construction industry is becoming increasingly aware of its actions and impact on the planet. Sandwich panels, which are an innovation in the construction industry, offer many environmental benefits that are worth noting. In this post, we take a look at how sandwich panels contribute to the environment and their environmental benefits.

Energy efficiency

Excellent thermal insulation

Sandwich panels are known for their excellent insulation properties. They use cores of highly insulating materials such as polyurethane, polystyrene or mineral wool. As a result, they help to maintain a constant temperature inside buildings, significantly reducing energy requirements for heating and cooling. Lower energy consumption translates into lower CO₂ emissions and other pollutants associated with energy production.

Reducing Energy Costs

Better insulation leads to lower energy-related costs. This not only means financial savings for building occupants, but also less impact on the environment, as less energy has to be produced and consumed.

Reduction of Waste Construction Materials

Precise Dimensions and Minimisation of Waste Materials

Sandwich panels are manufactured in factories with high precision, minimising construction waste on site. Thanks to their dimensions and readiness for use as soon as they are delivered, the amount of waste material and cutting that is common with traditional construction methods can be reduced.

Recyclability

Some sandwich panels, especially those with a polyurethane core, can be recycled. When dismantled or rebuilt, the panels can be recycled and used to make new materials, reducing environmental impact and landfill waste.

Speed of Assembly and Minimisation of Environmental Disturbance

Shorter construction time

Sandwich panels are quick to install, which means shorter construction times. Shorter construction project times reduce the use of energy and construction-related resources such as water and auxiliary materials. Less disruption to the environment during construction benefits local wildlife.

Reduced energy consumption during construction

Faster construction means less energy consumption during the construction process. This also reduces emissions and other pollutants associated with construction machinery.

High durability and longevity

Resistance to atmospheric conditions

Sandwich panels have a high resistance to weather conditions such as rain, wind, snow and extreme temperatures. Due to their durability, buildings made of sandwich panels require less maintenance and repair, which translates into less resource consumption in the long term.

Longer Life

The longevity of sandwich panels means that they will last for many years, reducing the need for frequent renovations and replacements. This also translates into less material consumption and less environmental impact.

Innovative Materials and Technologies

Sustainable Materials

More and more sandwich panel manufacturers are betting on sustainable materials and technologies. They are using recycled raw materials, naturally derived materials and technologies that minimise the environmental impact during production.

Energy Saving Technologies

Some modern sandwich panels are equipped with technologies such as reflective coatings that help to provide additional temperature control and optimise the energy efficiency of the building.

Summary

Sandwich panels offer many environmental benefits, which contribute to environmental protection. Thanks to their excellent thermal insulation, reduction of construction waste, speed of installation and high durability, they provide an environmentally friendly solution for construction. By choosing sandwich panels, you are not only investing in the energy efficiency and durability of your buildings, but also in sustainability and minimising your impact on the planet.