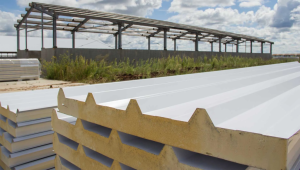

Sandwich panel technology is evolving rapidly, adapting to increasing demands for energy efficiency, aesthetics and building durability. The introduction of innovative solutions and materials is influencing the wide range of applications for sandwich panels, from industrial to residential construction. In this article, we take a look at the latest trends in sandwich panel technology that could influence the future of the construction industry.

1. Sustainability and ecological materials

Increasing attention is being paid to sustainability and green materials in construction. In the context of sandwich panels, this means:

- Recycled materials:

- Description: The introduction of recycled materials, such as recycled paper or plastic, into the production of sandwich panels is intended to reduce environmental impact.

- Benefits: Reduced waste, less consumption of natural resources, lower carbon footprint.

- Low-impact insulation:

- Description: New types of core, such as plant-based fibre or biocomposite cores, offer better insulating properties while having a lower environmental impact.

- Benefits: Reducing CO₂ emissions, improving the energy efficiency of buildings.

- Organic certification:

- Description: Sandwich panels are gaining environmental certifications, such as LEED or BREEAM, which confirm their sustainability.

- Benefits: Increasing attractiveness for customers seeking green building solutions.

2. innovation in materials and production technology

New technologies and materials in the manufacture of sandwich panels are bringing improvements in functionality and aesthetics:

- Nanotechnology:

- Description: Nanotechnology makes it possible to introduce coatings with self-cleaning, anti-bacterial or chemical-resistant properties.

- Benefits: Increased durability, easier maintenance, better resistance to contamination.

- New insulation cores:

- Description: Introduction of cores made from advanced materials, such as PIR (polyisocyanurate) foam cores or cores made from highly fire-resistant materials.

- Benefits: Improved insulation properties, increased fire resistance, improved durability.

- Extrusion and moulding technology:

- Description: Modern extrusion and moulding technologies allow the plates to be shaped with precision to create more complex and aesthetically pleasing forms.

- Benefits: Better fit for purpose, aesthetically pleasing finish.

3 Integration with intelligent building systems

Sandwich panels are increasingly being integrated with smart building technologies, which brings management and monitoring benefits:

- Monitoring systems:

- Description: Introduction of sensors and monitoring systems in sandwich panels that can track changes in temperature, humidity or load.

- Benefits: Better management of internal conditions, faster detection of problems.

- Integrated energy solutions:

- Description: Sandwich panels can be fitted with photovoltaic elements or energy recovery systems.

- Benefits: Increasing the energy efficiency of the building, reducing operating costs.

4 Personalisation and aesthetics

The increased importance of aesthetics in construction is prompting manufacturers to offer more varied finishing options:

- Variety of finishes:

- Description: New options for panel finishes, such as different textures, colours or surface effects, allow a better match with the architectural style.

- Benefits: Possibility to create a unique look for the building, better integration with the surroundings.

- Personalised plates:

- Description: Possibility to order sandwich panels with individually designed patterns or logos.

- Benefits: Highly personalised, the ability to promote a brand or specific design features.

5. increased automation in the production process

Automation in the production of sandwich panels contributes to improved quality and efficiency:

- Automatic production lines:

- Description: The introduction of automated production lines for the manufacture of sandwich panels allows faster production and higher precision.

- Benefits: Increased productivity, fewer errors, better quality control.

- Digital production management:

- Description: Use of production management software and real-time quality monitoring.

- Benefits: Better control of the production process, rapid response to problems, process optimisation.

A guide to the latest trends in sandwich panel technology: What's new on the market?

Summary

The latest trends in sandwich panel technology show, how dynamically the construction sector is developing. Sustainability, material innovation, integration with intelligent building systems, personalisation and production automation are key areas that are influencing the future of sandwich panels. The choice of modern solutions and technologies allows the creation of more efficient, durable and aesthetically pleasing buildings that respond to increasing market and environmental demands. Following these trends and implementing them in building projects can bring numerous benefits and competitive advantages.