Sustainability in construction is becoming a priority for architects, investors and contractors worldwide. In the face of increasing environmental awareness and tightening regulations on energy efficiency and CO2 emissions, the selection of the right building materials plays a key role in the implementation of sustainable projects. Sandwich panels, thanks to their unique properties, are one of the solutions that can make a significant contribution to the environmental performance of buildings. In this article, we will discuss how sandwich panels support sustainable construction, from production to use to recycling.

Sandwich panels and energy efficiency:

- High insulation properties: Sandwich panels have excellent insulation properties, which is key to minimising thermal energy losses in buildings. By using an insulating core such as polyurethane (PUR/PIR) or mineral wool, sandwich panels effectively reduce the energy required to heat or cool a building. The high thermal insulation performance leads to a significant reduction in energy consumption, which translates into lower operating costs and lower greenhouse gas emissions.

- Sustainable energy management: In industrial and commercial buildings, where sandwich panels are often used, energy efficiency is key to reducing operating costs and meeting energy efficiency standards. With sandwich panels, it is possible to design buildings with low energy consumption, which is important in the context of the move towards zero-energy or passive construction.

Sandwich panel production and sustainability:

- Ecological production processes: Modern sandwich panel production technologies are increasingly environmentally friendly. Manufacturers are paying attention to reducing CO2 emissions during production and minimising the use of raw materials. Many companies are implementing technologies that enable the recycling of production waste and the reduction of energy consumption in the production process.

- Selection of sustainable materials: Sandwich panels can be manufactured from materials that are sustainably sourced or recycled. For example, mineral wool cores can be manufactured from naturally derived raw materials such as basalt rock, making them more environmentally friendly. In addition, manufacturers are increasingly offering boards made from recycled raw materials, reducing the need for new natural resources.

Sustainable use of sandwich panels in buildings:

- Long life and durability: Sandwich panels are a building material with exceptional durability, which translates into a long service life and low maintenance costs. As a result, buildings made of sandwich panels not only perform their function for many years, but also require fewer resources for repairs and maintenance. This reduces the overall environmental impact, as structural components need to be replaced less often.

- Weather resistance: Sandwich panels are extremely resistant to external influences such as UV radiation, moisture, frost and corrosion. Thus, even in harsh climatic conditions, sandwich panels retain their insulating and aesthetic properties, which contributes to the sustainable use of the building.

Recycling and reuse of sandwich panels:

- Recyclability: One of the key aspects of sustainable construction is the recyclability of building materials at the end of their life. Sandwich panels, by virtue of their design, can be recycled, whereby core and cladding materials can be reused to produce new panels or other building products.

- Minimising construction waste: The use of sandwich panels in construction reduces construction waste. These panels are often manufactured to size, which minimises the amount of waste generated during installation. In addition, their lightweight construction makes them easier to transport and install, which also contributes to reducing the carbon footprint of the entire construction process.

The use of sandwich panels in sustainable building projects:

- Energy-efficient and passive buildings: Sandwich panels are the ideal material for the construction of energy-efficient and passive buildings, where achieving the highest possible energy efficiency is crucial. Thanks to their insulating properties, these panels help to achieve low energy demand, which is important in terms of reducing CO2 emissions.

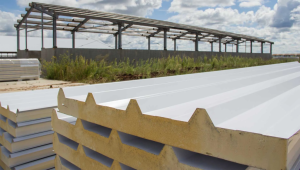

- Industrial and storage facilities: In industrial and warehouse facilities, which require large areas and are often built in a short space of time, sandwich panels prove themselves as a material that not only meets functional requirements but also contributes to sustainable goals. Their lightweight construction allows for quick construction and their insulating properties ensure energy efficiency in long-term use.

- Public and commercial facilities: In public and commercial projects, where not only functionality but also aesthetics and sustainability matter, sandwich panels offer many possibilities for personalisation. They can be used to create modern, eco-friendly facades that are not only beautiful but also energy-efficient.

Benefits of using sandwich panels in sustainable construction:

- Reducing CO2 emissions: Thanks to their high insulating properties, sandwich panels contribute to a reduction in energy consumption, which has a direct impact on the carbon dioxide emissions associated with heating and cooling buildings.

- Reduction in raw material consumption: The production of sandwich panels from recycled materials and their longevity contribute to a reduced need for new raw materials, which is important in the context of conservation of natural resources.

- Promoting a circular economy: The recyclability of sandwich panels and the minimisation of construction waste are part of a closed loop economy, where materials are reused and waste is reduced as much as possible.

Sandwich panels

Summary: Sandwich panels are a key element of sustainable construction, combining high energy efficiency, durability and recyclability. The choice of this material allows projects, which not only meet modern ecological requirements, but also contribute to the